Is International Competition Becoming A Major Problem For Manufacturers?

By 2025, India is expected to have a twenty-five percent hold on the manufacturing industry. It’s not the only country that might grab a bigger piece of the pie either. Arguably China is the heavyweight when it comes to manufacturing, but there are still a lot of businesses established in America as well. As the EU deal is finalized, Britain will want to boost its economy, improving exports and making trade deals. Therefore, we might see a growth in the manufacturing industry there as well. There are several other developing countries with economies that are growing rapidly and will be a bigger presence. All of these factors lead to one question for manufacturers. Do you need to be worried about international competition? It’s an interesting question and one that requires careful analysis.

Cheaper Production

One of the biggest issues for manufacturing businesses in westernized countries is that they are not playing on a fair field. Arguably, in certain countries, production costs are always going to be cheaper. This makes the businesses there more competitive. They are then able to win contracts from other companies. For instance, a lot of tech companies buy products from factories in developing countries.

One of the reasons for this is undoubtedly the labor laws. Human rights are poorer in developing countries. They continue to be in areas of Asia and Europe. Workers are paid minimum wage meaning that companies can hire a cheap workforce. In some areas, there are also limited laws against child labor. Again, this means a cheap workforce. Over the last several years, numerous popular brands have been hit with controversy. This occurred after it was revealed products were made using child labor.

That said, it is understandable why companies set up internationally. They want to cheapen production costs as much as possible. Doing this increases the overall revenue of their model. It’s not just about labor laws either. Certain countries have offered tax incentives for businesses to set up there for cheaper taxation. Puerto Rico is perhaps one of the latest examples of this, though it was not entirely successful.

Ease Of Access

Another reason for the growth of international manufacturing businesses is the ease of transportation. In the past, it made sense to buy products from manufacturers in the same country. Now, products can be shipped, transported and sold across oceans easily. Logistics businesses are making this process easier than ever, and businesses are taking advantage of it. This is one of the reasons why ninety-percent of products are manufactured in China. It may be quite a distance from countries where the products are sold. But shipping and air transportation is so simple it’s no longer a problem or a concern.

It’s clear that there are many advantages for companies buying products from international manufacturers. What does this mean for local manufacturers? It means that they have to step up their game. They need to cheapen production and become more competitive. They need to find USPs that make them a better choice for buyers. There are a few options manufacturers must consider here.

Quality Not Quantity

It’s an old message for sure, but one that companies would do well to heed. Rather than focusing on how many clients they are losing, they should focus on the ones that they have. They need to make sure that they are producing products that are higher quality than the competition. When you’re producing on the level that businesses in China are, things will slip through the cracks. We’ve already seen this occur with products needing to be recalled due to the materials used.

Local manufacturers who sell great products are going to win over more clients and customers. It is a distinct advantage that smaller firms have over larger manufacturing corporations.

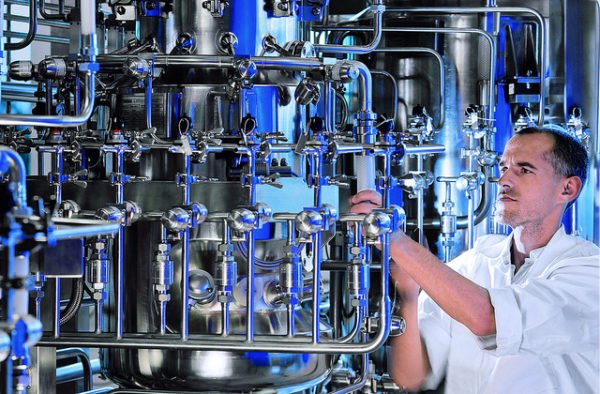

Cheaper Methods Of Production

Local manufacturers do need to make sure they are doing everything they can to cheapen the production process. This might mean investing in new technology or looking at more efficient processes. For instance, this product from ReliantFinishingSystems.com is used for powder coating. The process is cheap, effective and efficient, delivering a high-quality final result.

As well as this, producers should be looking at incorporating new forms of energy saving into the production model. Every year, new tech and equipment is introduced into the market. It is designed to save business owners a lot of money in the long term.

Outsource

If you can’t beat them, join them, or rather use their services. You should stop worrying about what international businesses are doing to the local industry. Instead, manufacturers should use the growth of international factories to their advantage. Outsource certain processes to a place where production costs are cheaper. Doing this, you’ll keep your product cheap and you will be able to get a larger quantity of items produced. The only issue is quality control. If you’re not making the product yourself, you have very little input into the quality. That’s why you need to choose the businesses that you partner with carefully. Don’t make the mistake of using a cheaper business that could damage the reputation of your brand.

Produce A Unique Item

You can look into producing something for the market that other companies can not make. This could be a unique product that requires a certain production method. If you own the copyright to a method of production, no other business will be able to make the same product. Many manufacturers have found success by making something unique to their company. Even if other companies do copy your idea, it’s always difficult to beat the original.

The International competition will not mean the death of local manufacturing companies. Local manufacturers just need to work to improve their business model. They need to make sure they are offering their consumers more at a cost friendly price. If they do this, they will be able to stay afloat in a sea filled with additional competition. Quality products will always win out over mass production, even in a dicey economic climate.