Shop owners agree that the clients of today’s manufacturers increasingly expect their suppliers to have in-house coordinate measuring machines. Internal quality assurance capabilities mean that you can guarantee reliability and the accuracy of the parts you deliver. Clients want to know that when they’re on the receiving end of parts, they’ll actually fit, without risking costly delays and corrections. There are an estimated 40,000 of these measuring instruments across North America. While you don’t want to get left behind by changing standards, there are some important things to ask yourself before you go out and invest.

Purpose of Inspection – What’s your goal in bringing metrology equipment into your business and training your staff to become competent users? Do you plan on inspecting every part to come out of your facility or just lot samples? Do you want to integrate your quality assurance process into the production line, allowing to you to fix tool errors with rapid feedback?What’s the practical purpose of all of the data coordinate measuring machines can gather for you?

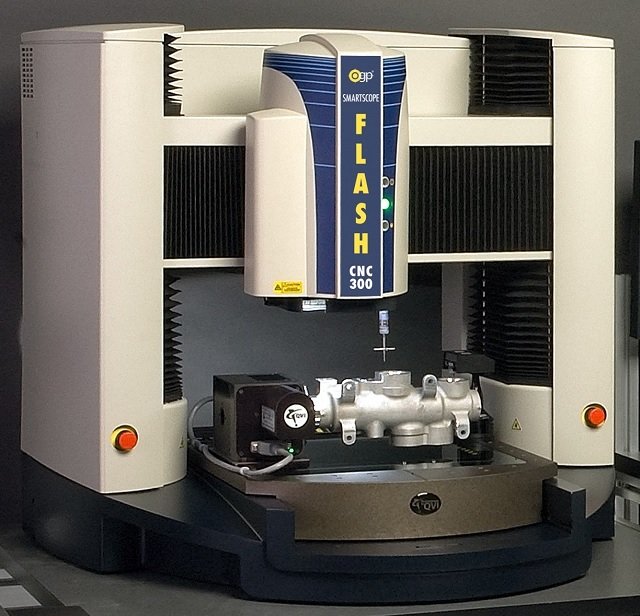

Compatible Parts – A common mistake made by businesses purchasing a coordinate measuring machine is wanting a one-size-fits-all solution. Look at the majority of the components you need to inspect and choose the tool that will deliver the fastest and most accurate results for those pieces. Just because you make parts that are too big to fit your workhorse doesn’t mean that bigger is always better. Over capacity is wasteful, and it’s not just the cost, it’s also the footprint. It isn’t time to consider pieces like Gantries and horizontals until bigger components become a bigger part of your business.

The Best Tool for the Job – If your operators find it quicker and easier to measure something with a caliper, they will. You have to ask yourself where new investments will actually make the process more efficient and where they can actually slow things down.

Working with a full-service metrology equipment supplier can help you answer all of these questions. Today’s companies are not just retailers but partners throughout the lifespan of your new equipment. CMM (Canadian Measurement-Metrology), for example, will evaluate the space and conditions of the area where your instrument will go before installation and assess its applicability to job. They also handle installation, calibration, and training operating staff.

CMM measuring instruments have never been more important for attracting new business. Internal inspection abilities are a sign that a company can handle fast turn-around, correct production flaws as they happen, and mitigate delays. It’s an investment that will grow your reputation for reliability and on-time delivery. Seeking the help of a hands-on vendor like CMM is a way to tailor metrology solutions to your custom requirements. They can advise you on the appropriate probing, scanning, and data collection methods for the task, and provide regular calibration and repairs. Preventative maintenance can prolong the life your investment by decades and avoid breakdowns. Contact a measurement solutions provider today to learn more about the growing role of coordinate measuring machines.